Above: Side tables we finished in “French polish”.

Finishing & Stripping Options

At the 3 restorers workshop we can provide a wide range of traditional and modern hand finishes including:

• Shellac based finishes such as ‘French polishing’

• Danish oil, Osmo and other oils

• Wax finishes

• Water based varnishes

• Water based paint

• Ebonizing

For more details about finishes, please see further down this page.

Above: Partially stripped Victorian nursing chair.

Furniture Stripping

We provide a full hand-stripping and prepping service, so if you have a tired piece of furniture in need of a ground-up restoration from bare wood – No problem.

Please note; We do not use ‘dipping’ to strip furniture so you don’t need to worry about the damage / devaluation associated with that process – We only ever strip furniture by hand(!).

Above: ‘Before’ and ‘After’ shots of an Alvar Aalto for Finmar, Birch veneered chest of drawers we restored.

Furniture Repair & Restoration

We carry out all kinds of structural and finish repairs to wooden furniture of all periods. Whatever it is you need – we probably do it. Please ask us and we can discuss options.

hello@3restorers.com

Above: Oak chair, completely disassembled for joint repairs.

Carving Repairs

Below are a couple of pictures of some previous clients’ projects we have worked on. In these cases we had to hand carve replacement elements of the pieces that had been lost over time. We then had to colour, polish and artificially ‘age’ the replacement parts to blend in with the surrounding original finish…

Above: Mid restoration – new, hand-carved claws attached…

Above: The finished and ‘French polished’ foot/paw.

Above: Hand-Carved Replacement Bracket.

Furniture Finish Types

Overview ~

There are many ways to finish a piece of furniture. It would be impractical describe all of them but to help you choose what might be most suitable for your project in terms of aesthetics, period appropriateness and durability, we have gone into some detail below about four of the main hand finishes that we offer; Shellac, Danish Oil, Osmo and Varnish.

Shellac / French Polish ~

“French Polish” is a term wrongly used to describe shellac. Shellac is a substance secreted by the Lac Beetle which is used for many purposes including painting finger nails and finishing furniture. We use many furniture finishing products containing shellac, which have various colours, viscosities, sheen levels and filling properties depending on the process they’re needed for. One such finishing process – The most well known one – Is ‘French Polishing’. A French Polished finish is an extremely high-sheen finish used on certain styles of furniture mainly from the 19th Century – for many other antique pieces it is not appropriate.

Where a French Polished surface is required, we apply shellac to flat surfaces using the traditional process of layering up polish many, many times with a cloth and wadding applicator known (confusingly) as ‘a rubber’. We have to wait for each layer of shellac to dry throughout the process. The first few layers of polish actually sink into the wood considerably and therefore must be left for a day or more before we can continue. As we go along, the polish is gradually thinned down using alcohol. We must also periodically cut back the layers of polish with increasingly fine abrasives. Next we go over the surface with pure alcohol, then with an extremely fine cutting compound, and finally with a finishing wax. Needless to say, this is not a quick process(!) but the resulting, incredibly beautiful, deep, mellow shine simply isn’t achievable by any other means.

For items which have some irregularly shaped components – A table with a flat top and heavily carved legs for example; we can match the French polished top to it’s legs even though it’s not possible for any French polisher to use a polishing rubber on heavily carved legs. To do this we use the correct traditional tools called ‘polishing mops’, which are extremely fine brushes of various sizes, made from squirrel hair. These are used in much the same way as the rubber to gradually apply, then cut back very, very thin layers of shellac which fill the wood grain until the desired level of sheen is achieved.

Durability & Maintenance: shellac finishes are relatively delicate compared with modern finishes. Particular care must be taken to avoid any liquids from getting onto the surface especially alcohol. Routinely coating the surface with furniture wax will help to protect it.

Breathable finish? No.

Above: A burr Walnut games table top that we “French polished”.

Danish Oil ~

Danish Oil is the name used for a finishing product made by many different manufacturers to varying ‘recipes’. They’re generally pretty similar products though quality varies significantly. They contain a blend of oils, typically; Tung Oil and Linseed Oil plus drying agents etc.

Danish Oil is widely used to finish/re-finish ‘Mid Century Modern’ furniture, I.e; 20th Century furniture, typically made during the period from around 1950 to 1978. Many of the original and most iconic examples of this style of furniture came from Denmark and Scandinavia in general, hence the name ‘Danish Oil’.

This stylish, post WWII furniture soon caught on elsewhere and cabinet makers and architects in the UK, North America and other parts of Europe began to take heavy stylistic and constructional cues from the Scandi’ originators.

If you have a piece of furniture in this style; Simple, modern lines, lack of applied ‘fussy’ decoration, prominent use of Teak or Rosewood etc. Then it is quite likely to be finished in Danish oil, even if it is an English piece (Gplan, Nathan for example). If you’re in any doubt, you can always send us some photos of your furniture and we’ll be happy to discuss.

Durability & Maintenance: Danish Oil is a lot more durable than shellac and may tolerate water for short periods. Water left on the surface for prolonged periods (under a vase for example) will likely still damage the finish. Maintaining a Danish Oil finish with subsequent coats is relatively straight forward and may not require a skilled crafts-person.

Breathable finish? Yes.

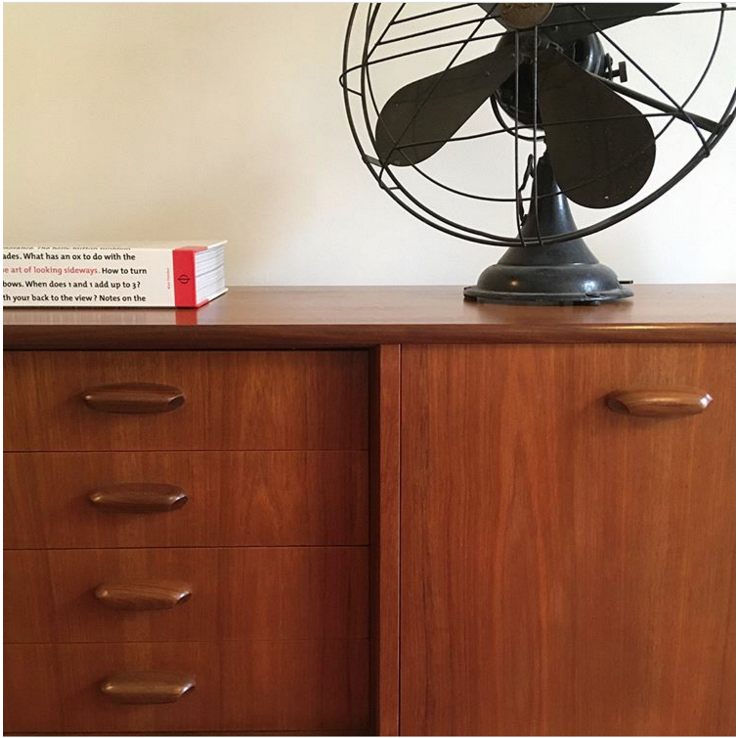

Above: A Danish Oil finish seen here on a Mid Century, Teak sideboard that we restored. This finish is typical on furniture of this style and period, particularly on Scandinavian furniture.

Osmo ~

‘Osmo Oil’ or ‘Osmo Polyx-Oil’ to use the full title, is the name of a range of branded wax-oil blended finishing products. Wax-Oils are a modern hand-finishing product with various sheens, tints etc available. Wax-Oils can be great if you want a finish similar to Danish Oil but you require more durability. They’re also great for certain effects, for example; a raw, ultra-low sheen, almost bare wood look or a colour tint. They can also sometimes be used to put a more contemporary twist on an older piece.

Durability & Maintenance: Wax-Oils are generally much more durable than shellac and more durable than Danish Oil with some variants even suitable for finishing floors.

Maintaining a Wax-Oil finish with occasional subsequent coats is relatively straight forward and may not require a skilled crafts-person.

Breathable finish? Yes.

Above: We refinished this Mid Century, North American chair by Norman Cherner using Osmo Polyx Oil products.

Varnish ~

In some instances hand applied Varnishes can be a great choice for 1960s furniture particularly on pieces made with wood varieties that don’t tend to take oil well (Beech for example). We’ve used them to great effect refinishing vintage Ercol pieces.

Durability & Maintenance: Generally very durable, though ‘varnish’ is a broad field. Some varnishes can be coated with furniture wax as a final finish – if this is the case then the wax would need to be maintained. If wax hasn’t been applied then the is no routine re-coating of the varnish in terms of maintenance.

Breathable finish? No.

Above: We refinished the tops of these Ercol “Pebble” side tables to blend with the original, factory varnish on their legs.